Understanding concrete crack repair

Introduction to Concrete Crack Repair

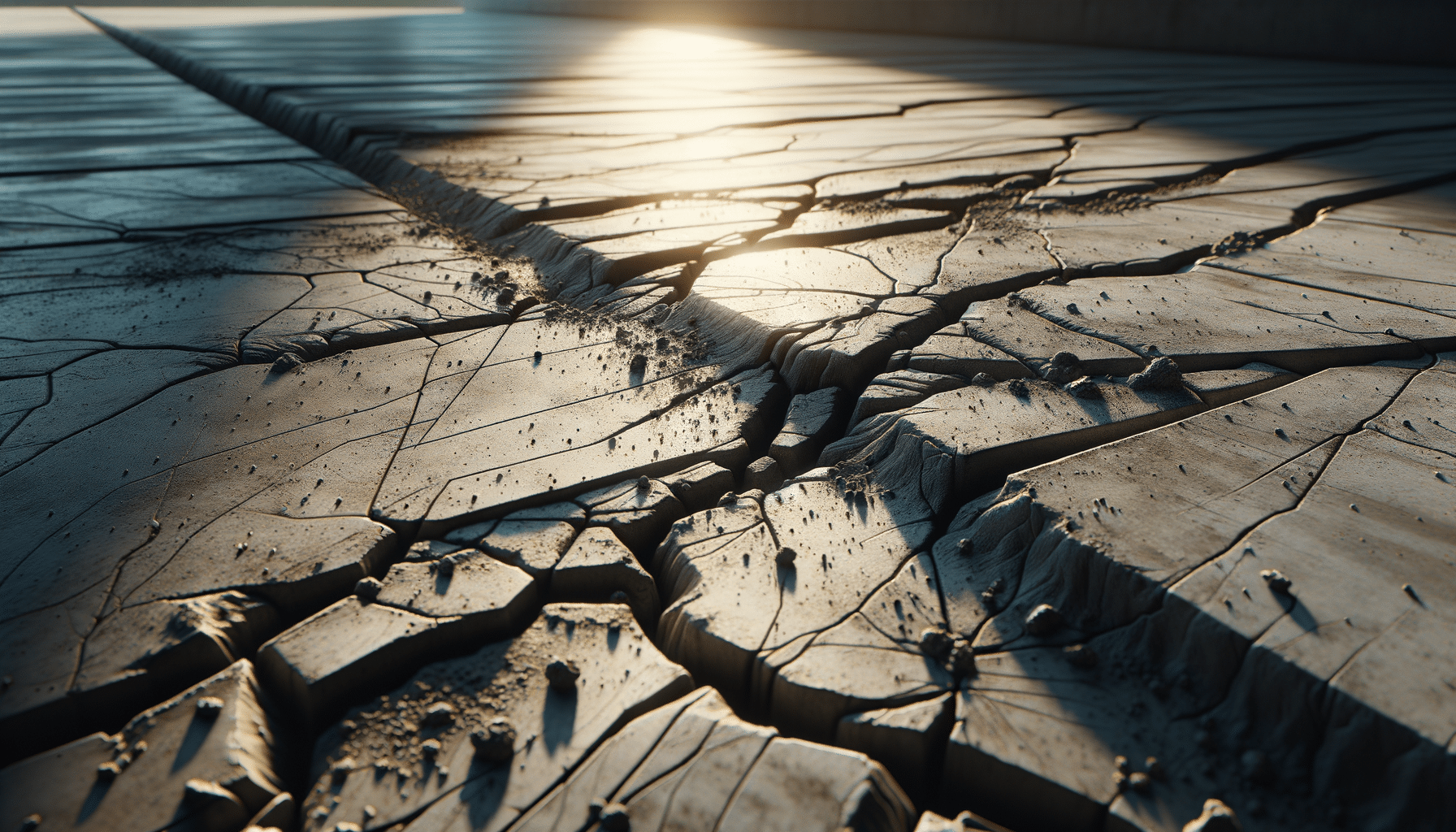

Concrete is a fundamental building material used in various structures, from residential sidewalks to towering skyscrapers. However, over time, concrete surfaces can develop cracks due to a variety of factors such as weather, movement, or settling. These cracks can compromise the structural integrity and appearance of the concrete. Therefore, understanding the methods of concrete crack repair is essential for maintaining the longevity and safety of concrete structures. This article delves into the intricacies of concrete crack repair, exploring different techniques and materials used to restore concrete surfaces effectively.

Causes of Concrete Cracks

Before diving into repair methods, it is crucial to understand the underlying causes of concrete cracks. These can range from environmental factors to issues related to the concrete mix itself. Common causes include:

- Thermal Expansion and Contraction: Changes in temperature can lead to the expansion and contraction of concrete, resulting in cracks over time.

- Subgrade Settlement: Improperly compacted subgrade or soil erosion can cause the concrete to settle unevenly, leading to cracks.

- Overloading: Excessive weight or pressure on concrete surfaces can cause them to crack or fracture.

- Shrinkage: As concrete dries and cures, it naturally shrinks. If not properly controlled, this shrinkage can lead to cracking.

Identifying the cause of the cracks is the first step in selecting the appropriate repair method, ensuring that the repair will be durable and effective in preventing future issues.

Repair Techniques for Concrete Cracks

There are several techniques available for repairing concrete cracks, each suited for different types and sizes of cracks. Some of the most common methods include:

- Epoxy Injection: This technique involves injecting a high-strength epoxy resin into the crack, bonding the concrete back together. It is ideal for structural cracks that require load-bearing capacity restoration.

- Routing and Sealing: This method involves routing out the crack to create a clean, uniform groove, which is then sealed with a flexible sealant. It is suitable for non-structural cracks exposed to weather or moisture.

- Stitching: Metal staples or stitching dogs are used to hold the crack together. This method is often used in conjunction with epoxy injection to provide additional support.

- Gravity Filling: For hairline cracks, a low-viscosity resin can be poured over the surface, allowing it to seep into the cracks and seal them.

Each technique has its advantages and limitations, and the choice of method often depends on the crack’s size, location, and the concrete’s overall condition.

Materials Used in Concrete Crack Repair

The choice of materials in concrete crack repair plays a significant role in the repair’s success and longevity. The materials must be compatible with the existing concrete and capable of withstanding the conditions the concrete will face. Common materials include:

- Epoxy Resins: Known for their high strength and bonding capabilities, epoxy resins are frequently used in structural crack repairs.

- Polyurethane Sealants: These sealants are flexible and water-resistant, making them suitable for sealing cracks exposed to moisture.

- Hydraulic Cement: Used for quick repairs, hydraulic cement sets rapidly and expands slightly as it hardens, filling the crack effectively.

- Silicone Sealants: Often used for exterior cracks, silicone sealants are highly resistant to UV rays and weather conditions.

Choosing the right material is crucial for ensuring that the repair will not only fix the crack but also prevent future cracking.

Preventive Measures and Maintenance

While repairing existing cracks is important, implementing preventive measures can significantly reduce the occurrence of new cracks. Here are some strategies to consider:

- Proper Curing: Ensuring that concrete is properly cured after pouring can prevent shrinkage cracks.

- Regular Maintenance: Inspecting concrete surfaces regularly and addressing small cracks promptly can prevent them from expanding.

- Control Joints: Installing control joints in large concrete slabs can accommodate movement and prevent random cracking.

- Sealing: Applying a high-quality sealer to concrete surfaces can protect them from moisture and chemical damage.

By taking these preventive measures, property owners can extend the lifespan of their concrete surfaces and avoid costly repairs in the future.

Conclusion: Ensuring Longevity with Concrete Crack Repair

Concrete crack repair is an essential aspect of maintaining the durability and appearance of concrete structures. By understanding the causes of cracks, selecting appropriate repair techniques, and using the right materials, property owners can effectively restore their concrete surfaces. Moreover, implementing preventive measures can significantly reduce the likelihood of future cracks, ensuring that the concrete remains in excellent condition for years to come. Whether for residential, commercial, or industrial applications, knowledge of concrete crack repair is invaluable for preserving the integrity and value of concrete structures.