A Guide to Small Bulldozer Pricing

Introduction to Small Bulldozer Pricing

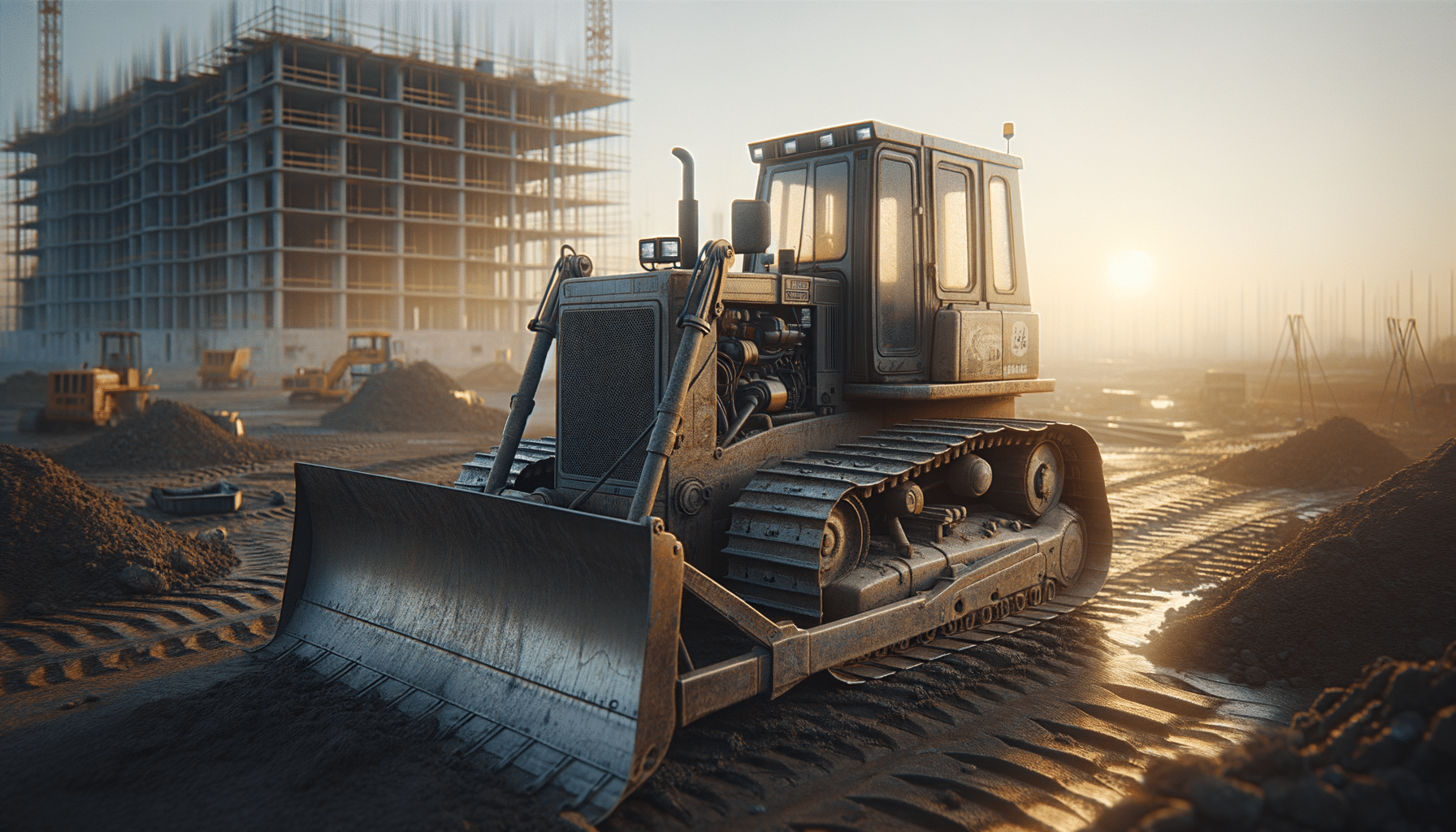

In the construction industry, small bulldozers are essential for a wide range of tasks, from site preparation to landscaping. Understanding the pricing of these machines is crucial for businesses and individuals looking to invest in equipment that meets their operational needs without breaking the budget. Factors such as engine power, size, and available attachments significantly influence the cost. Additionally, whether you opt for a new or used model can make a substantial difference in pricing. This article aims to provide a comprehensive guide on small bulldozer pricing, helping you make informed decisions based on your specific requirements and budget constraints.

Factors Influencing Bulldozer Pricing

When it comes to pricing small bulldozers, several key factors come into play. First and foremost, engine power is a major determinant. Bulldozers with higher horsepower tend to be more expensive due to their enhanced capability to handle heavy-duty tasks. The size of the bulldozer also plays a critical role; larger models often come with a higher price tag, reflecting their increased capacity and versatility.

Attachments and additional features can further influence the cost. For instance, bulldozers equipped with advanced GPS systems or specialized blades for specific tasks may command a premium. Moreover, brand reputation is an important consideration. Brands known for their reliability and durability often price their equipment higher, but this can be a worthwhile investment in terms of long-term performance and reduced maintenance costs.

Finally, the choice between new and used bulldozers can significantly impact pricing. While new models offer the latest technology and warranty protection, used bulldozers can provide substantial savings upfront. However, buyers should carefully assess the condition and service history of used machines to ensure they are making a sound investment.

New vs. Used Bulldozers: Pros and Cons

Deciding between new and used bulldozers involves weighing the pros and cons of each option. New bulldozers come with the advantage of the latest technology, improved fuel efficiency, and the security of a manufacturer’s warranty. These factors can be particularly appealing for businesses looking to minimize downtime and maintenance costs.

On the other hand, used bulldozers offer a more budget-friendly option, often costing significantly less than their new counterparts. This can be an attractive choice for small businesses or those with limited project scopes. However, buyers must be diligent in inspecting used equipment for wear and tear, as well as ensuring that all necessary maintenance has been performed.

Ultimately, the decision will depend on the specific needs of the buyer, including budget constraints, the scope of projects, and the importance of having the latest features and technologies. Both new and used bulldozers have their place in the market, and understanding the trade-offs can help buyers make informed decisions.

Understanding the Role of Operating Weight and Project Use

The operating weight of a bulldozer is another important factor that can influence its price. Heavier machines are typically designed for more demanding tasks and may come with a higher cost. This is particularly relevant for projects that require significant earth-moving capabilities, such as large-scale construction or mining operations.

Additionally, the intended use of the bulldozer should guide purchasing decisions. For example, bulldozers used in urban environments might prioritize compact size and maneuverability, while those used in rural or undeveloped areas might focus on power and durability. Understanding the specific requirements of your projects can help you choose a bulldozer that provides the best value for your investment.

By considering both the operating weight and the typical use scenarios, buyers can ensure that they select a machine that not only fits their budget but also performs effectively in their specific applications.

Conclusion: Making Informed Purchasing Decisions

The process of purchasing a small bulldozer involves careful consideration of various factors, including pricing, engine power, size, and additional features. By understanding these elements and how they affect cost, buyers can make informed decisions that align with their operational needs and financial capabilities.

Whether opting for a new or used model, it’s important to evaluate the specific demands of your projects and the long-term benefits of different machines. By doing so, you can ensure that your investment not only meets immediate needs but also provides reliable performance and value over time.

Ultimately, a well-informed approach to purchasing can lead to a more efficient and cost-effective operation, allowing businesses to maximize their resources and achieve their project goals with confidence.